Hitachi Plant Construction provides broad construction and maintenance services of various plants worldwide as a plant manufacturer. We install the equipment and pipes fabricated by each manufacturer on site according to detailed construction plans and designs, connecting cables and pipes to operate together as a single plant. Various industries take advantage of our simulation analyses, various construction methods, detailed design and other technologies including plant designs and construction.

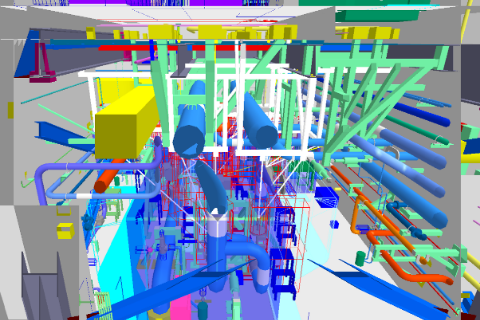

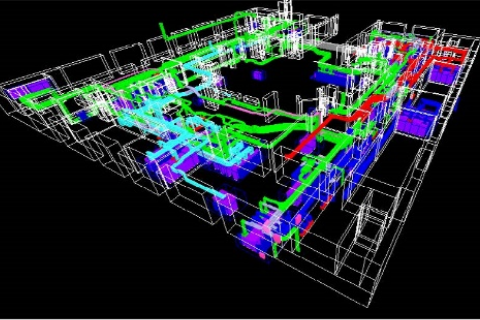

Hitachi Plant Construction provides pipe support, control platforms, planning and design of modules for integrated delivery and installation, construction planning, and structural stress analyses using 3D CAD systems.

Hitachi Plant Construction has provided the engineering necessary to address needs by designing plant piping using 3D-CAD systems. We succeed in fabricating high-quality products under a seamless management system that continues to utilize the 3D CAD data from the design phase throughout the manufacturing process.

Hitachi Plant Construction has adopted high-frequency induction bending to achieve flexible designs from the radius to the angle to bend pipes. Continuous and dynamic bending also dramatically decreases welded areas. By achieving highly efficient piping routes and reducing the number of weldings in a designated area, we are able to prefabricate low-cost pipes.

Hitachi Plant Construction plans and designs routes for cabling, instrument systems, and piping using 3D CAD systems as well as creates installation designs and arranges the materials for large-scale nuclear power and other plants.

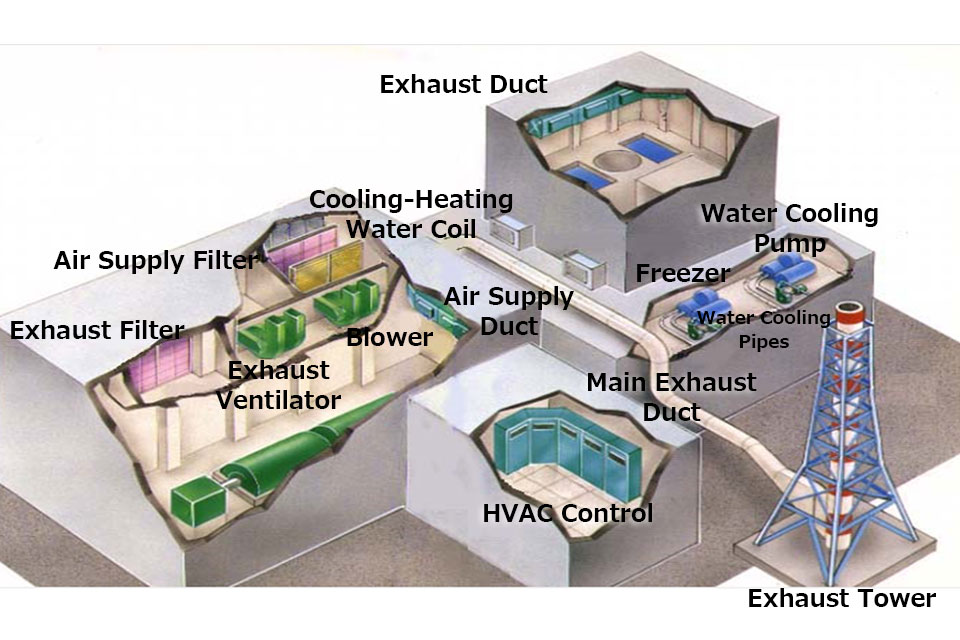

Hitachi Plant Construction builds highly reliable equipment throughout all Heating, Ventilation, and Air-Conditioning (HVAC) using consistent control systems from system planning through commissioning.

Extensive experience, expertise, and sophisticated technology development capabilities provide HVAC systems that adapt to the various needs of each customer.