Hitachi Plant Construction analysis technologies strive to support solutions to problems everyone can understand by reproducing and visualizing invisible and hard to replicate phenomenon via computer simulations.

As the Hitachi Group team at the forefront of analyses, we meet customer needs by using CAE, evaluation technologies, and expertise cultivated by supporting diverse industrial equipment analyses primarily for power plants.

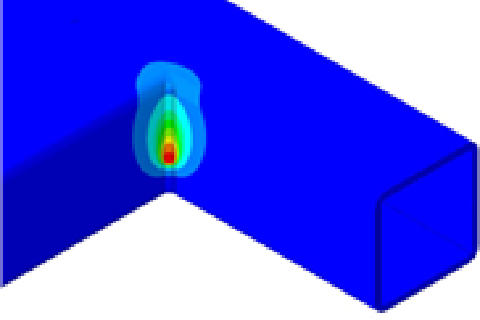

Simulation of Weld Residual Stresses

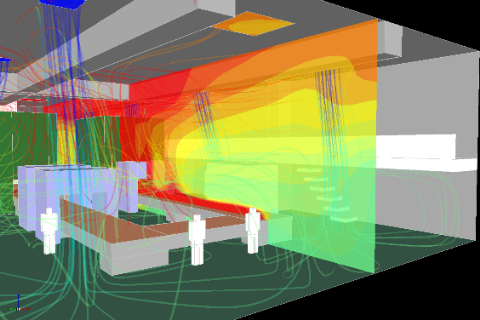

Simulation of Plant Ventilation

Get insight into the spread behavior of smoke and temperature variations due to fires in plants, warehouses, and other buildings to use in examining problems and improvements to fire prevention and detection systems.

Water flow analyses not only simulate gas and liquids but also solids and liquids imitating carriers and other catalysts supports as well as vibrations to evaluate liquid surface and other behavior.

These analyses are effectively used for applications such as aeration stirring basin, MBR treatment, and other simulations for water treatment facilities, river and other water level simulations during floods, flow velocity behavior in pipes, cavitation prevention measures, and other equipment simulations, and evaluations of the efficiency of water heat storage tanks and other building simulations.

Structural analyses obtain deformation, stress, and strain results for torque, velocity, stress, displacement, heat, and a variety of other loads.

These analyses can even verify the limit strength by taking into account various nonlinear behavior. These results help in not only reviewing designs but also in identifying and creating measures to prevent the cause of accidents.

Fluid dynamics analyses can simulate a board range of phenomenon, such as plant pipe flow, pumps, turbines and other fluid machinery, HVAC and cooling water systems, and overflow caused by agitating liquid surfaces. These results can support fluid-related development, greater efficiency, a better environment, and measures to prevent troublesome issues. These simulations visualize the invisible.

Thermal analyses simulate the heat distribution from the transfer of heat. These simulations can obtain deformation, stress, and strain results for temperature fields.

Engineers can grasp the heat distribution of products and verify heating and cooling conditions.

These specific simulations perform fire, magnetic field, machinery, optimization, and coupled analyses.

Collision analyses simulate dynamic behavior with short yet strong nonlinear properties, such as falling structures and other types of collisions.

For example, these simulations can determine the potential outcome of a structure in a fall or collision by taking into account the plasticity, failure, and strain rate dependency of the material.

Vibration analyses can obtain the eigenvalues of structures or the response to dynamic loads.

For example, engineers can run a vibration analysis that takes into account resonant frequency of earthquake loads and other vibrations to investigate potential outcomes. These analyses can even take into account various nonlinear behavior.

Engineers can process the analysis results and confirm whether a work product satisfies standards or requirements by running an analysis that applies those standards or requirements, such as primary stress, primary plus secondary stress, and even fatigue evaluations.

We support preliminary assessments in the product design stage through analyses.

This helps with product evaluations and provides advantages such as shorter development timelines.

We support customers who lack the necessary resources, such as insignificant staff to run analyses or a lack of software licenses to run many simulations with many different parameter settings.

We support the troubleshooting essential to discover causes and create countermeasures through analyses.

We help customers who want to start using CAE by providing assistance and education on adoption and use so that everyone can take full advantage of CAE.

Cooperation with the Hitachi Research Institute and other Hitachi Group companies connects customers with Hitachi Group technologies in an effort to help them overcome their challenges.

These services assist customers in creating large-scale and complex models.

Hitachi Plant Construction uses ANSYS Fluent and various other CAE software to provide these analysis support services.

Please carefully read and agree to the terms and conditions in our Privacy Policy before contacting us. Please contact us using the contact information below only if you agree to our Privacy Policy.

Contact: Analysis Engineering Dept.

*Please ask for the person in charge of simulations when contacting us.